-

×InformationWindows update impacting certain printer icons and names. Microsoft is working on a solution.

Click here to learn moreInformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

-

×InformationWindows update impacting certain printer icons and names. Microsoft is working on a solution.

Click here to learn moreInformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

- HP Community

- Archived Topics

- Desktops (Archived)

- Scott, thank you very much for your detailed description...

Create an account on the HP Community to personalize your profile and ask a question

05-26-2015 04:20 AM

In the link you added, some newer/other Noctua low noise adapters are mentioned, LNA 'NA-RC10' = 51Ω

ULNA 'NA-RC12 = 147.5Ω.

I have never seen these available in the shops. 147.5 Ohm seems rather high, some fans may not even start spinning.

Though it would be interesting to see how this NA-RC12 would work out on the chipset fan of the xw6600.

In Europe the NA-RC7 seems the only Noctua low noise adapter available as a seperate product (3-pack).

Unfortunaly, other Noctua reducers are only sold as part of their fan-kits.

I may send an email to Noctua with a request for a custom order of their other adapters.

07-18-2015 04:38 PM - edited 07-19-2015 04:12 PM

It took a while, but here it is, as promised:

THE HP xw SERIES THERMAL SENSOR (TRANSISTOR) SWAP TUTORIAL

In order to get this job done, you will need:

- A putty knife and small (nail) scissors

- A soldering iron, preferably < 25 Watts with a small tip

- Heatshrinks

- a couple of 2n3904 transistors (these things cost next to nothing , so you'd better buy some spares).

1.

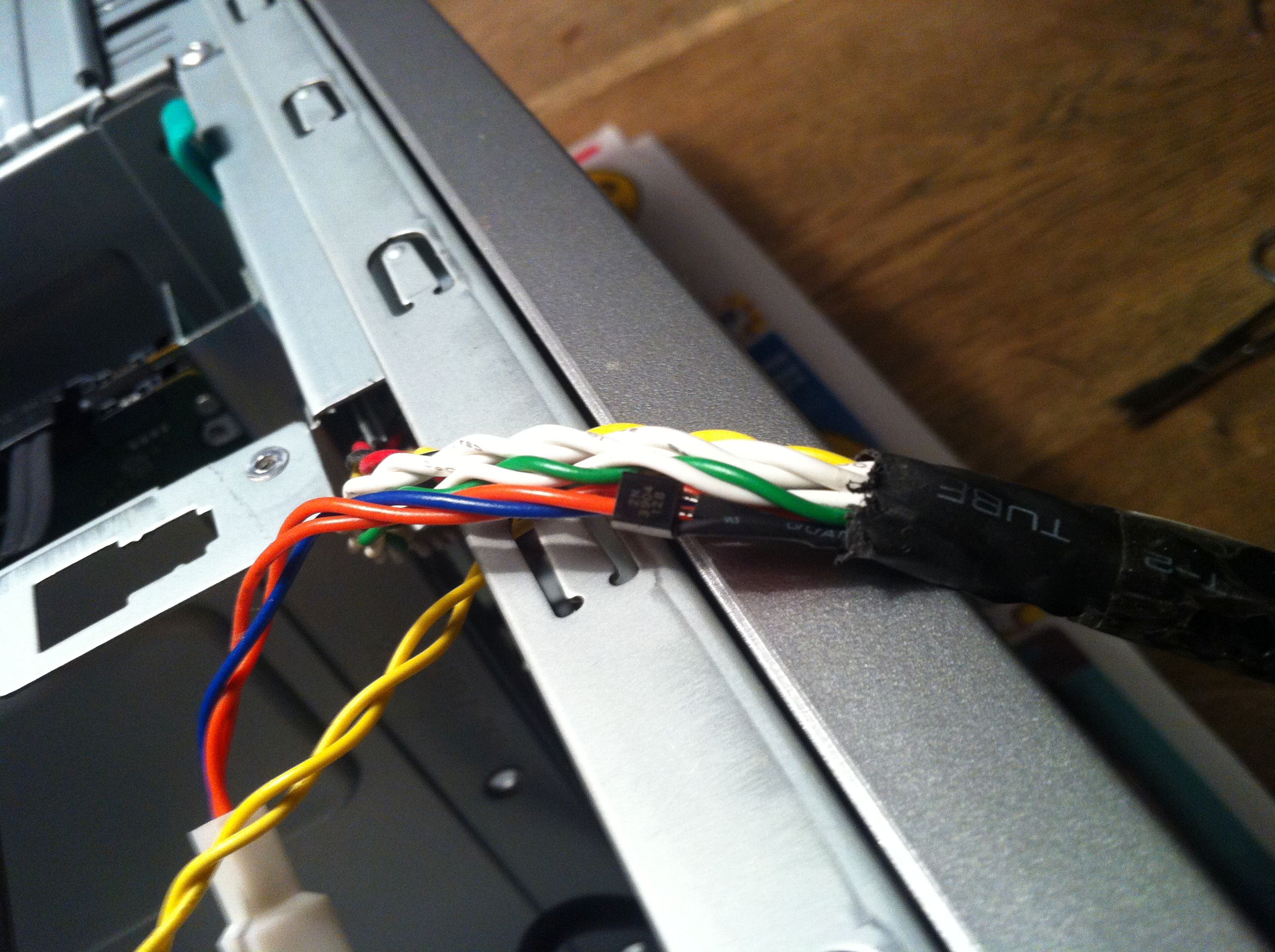

The 2n3904 transistor is 'hidden' in the Power/Loudspeaker/etc. cable assembly, as shown here:

2.

With a putty knife and nail scissors I carefully removed the heat shrink to 'uncover' the transistor:

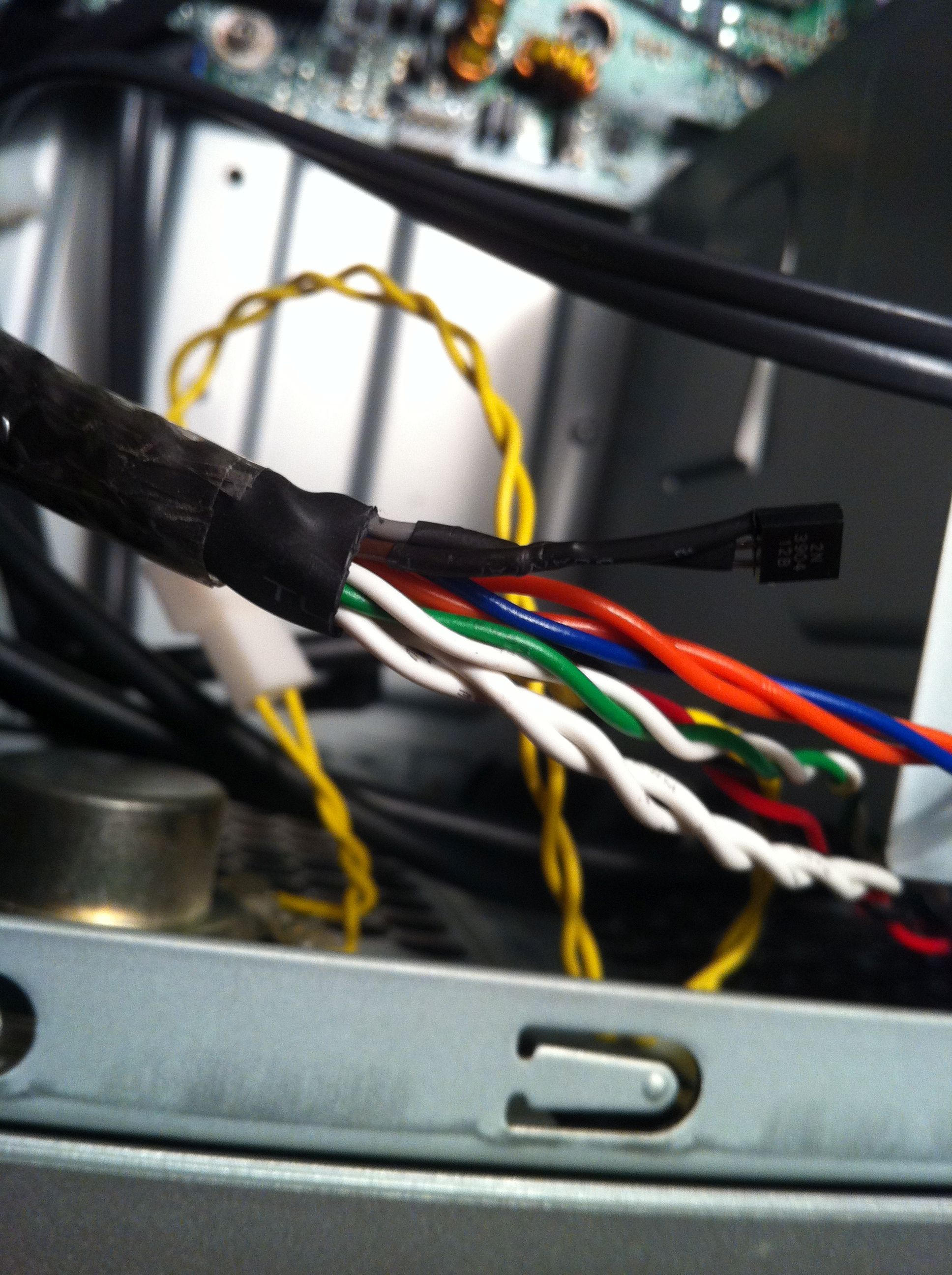

Further stripping:

And finally:

On the image above the emitter (soldered to the brown wire) and the base + collector (both soldered to the grey wire) are clearly visible.

3.

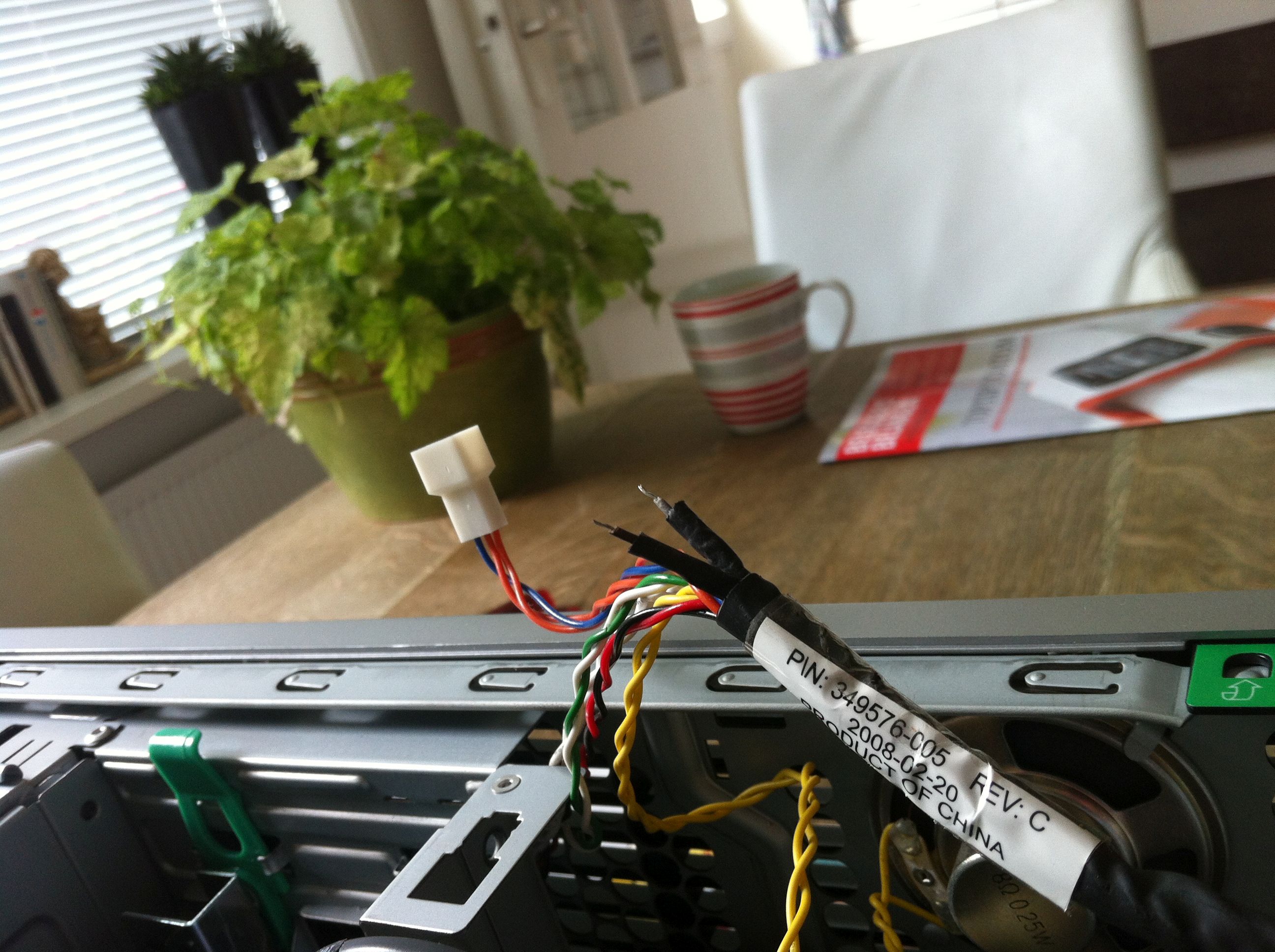

The old transistor has been cut off, the wires stripped and new heatshriks have been placed.

The wires are easily damaged or cut during stripping the mantle, so be gentle.

4.

Now it is time to actually solder a replacement 2n3904 transistor to the wires.

As I stated in the first paragraph, a low power soldering iron with a small tip should be used. My 16 Watt Ersa is perfect for this task. Unfortunately the tip is worn out and I did not want to wait for a new set of tips to arrive, so I used my 25 Watt white label iron with a Weller tip.

Apparently I forgot to take pictures immediately after soldering, therefore the image below is the only option to show the result.

Probably due to the heat of the soldering iron the fresh heatshrinks have become useless. At this stage I decided to 'stick' another transistor in parallel to check proper operation of the first one.

When I booted the xw6600, the fans seemed to be spinning at the same speed(s) as before the transistor swap. At least, I could not notice a significant difference.

Only two possibilities were left:

1. The PWM-controller on the systemboard has gone bad.

2. There is no faulty component; the fans are spinning at 'default' velocity, which is obviously loud.

In order to verify no. 1 (PWM) I decided to cut off my meticulously soldered transistor and boot the xw6600 without it.

Usually, post bios, one or two fans start spinning at a slighty higher velocity. I guess these are either the chipset fan or the memory fan, or both.

Without the 2n3904 transistor, post bios, initially (for some seconds) the same behaviour could be observed.

But then.... after 2-4 seconds it seemed 'someone had dropped turbo-prop inside my xw6600 and launched it'.

Though my xw6600 was obviously louder than before, I actually liked the sound.

I was glad to conclude the PWM controller was still fully functional and subsequently I soldered another 2n3904 to the wires.

4.

As shown previously, the first pair of heatshrinks already shrank during soldering. I took another heatshrink which I first cut in half and then each of the two smaller shrinks over their length. So , the heatshrinks could be wrapped around the wire / soldered transistor. As a precaution, I would advise to have both cutted half 'faced outwards', as shown in the image below. Actually, only form the left heatshrink are the 'two sides' visible.

Finally, a larger heatshrink is used to cover and protect the transistor.

I used a hair dryer for the 'shrinking'.

Done!

The original 2n3904 in my xw6600 appeared not be defective. Still, this small tutorial may be helpful to other owners/users of HP workstations.

In order to slow down the speed of some of my fans, I will install fan speed reducers.

These will probably be Noctua NA-SRC7, as advised by Scott (SDH).

- « Previous

-

- 1

- 2

- Next »

Didn't find what you were looking for? Ask the community