-

×InformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

-

×InformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

- HP Community

- Desktops

- Business PCs, Workstations and Point of Sale Systems

- Repair 7/15 socket that is nearly inaccessable. Damage prev...

Create an account on the HP Community to personalize your profile and ask a question

05-14-2022 12:01 PM

I have an HP Z800 that was brutalized prior to my ownership. The damage is slight involving the sata 7/15 HDD connector being torn from its mounting but its still there. However it is skewed enough to render it unusable for HDD in that tray.

I need to get behind the connector somehow and reset it, or otherwise cobble it up so it can be used. It appears to be nearly butted against what would be the right hand side of tower near the bottom.

That is the side with no door... so not really sure how to get to the back side of connector.

I really hope someone here will understand what the problem is and at least help me get some of the internal covers removed.

The internal cover on the 5.25IN bays in particular. It appears to be supposed to swing out toward front of machine but seems stuck.

I'm considering extending the injured connector with extension cable but there is very scant space inside the drawer where the connector is. Even if I ran the cable out of the tray, there is still the problem of where to place the HDD.

One of the hdd drawers is missing the little mechanism that pops the drive loose from plug to allow drawing it out... so one drive cannot be moved without forcing it.

And, of course, it is the drive drawer right below the damaged sata connector... so making it even harder to access. At least I can and am using the HDD that is stuck in there.

I need diagrams or pictures of the inside of HP Z800 tower. And of the internal covers. I'm not finding them by google searches.

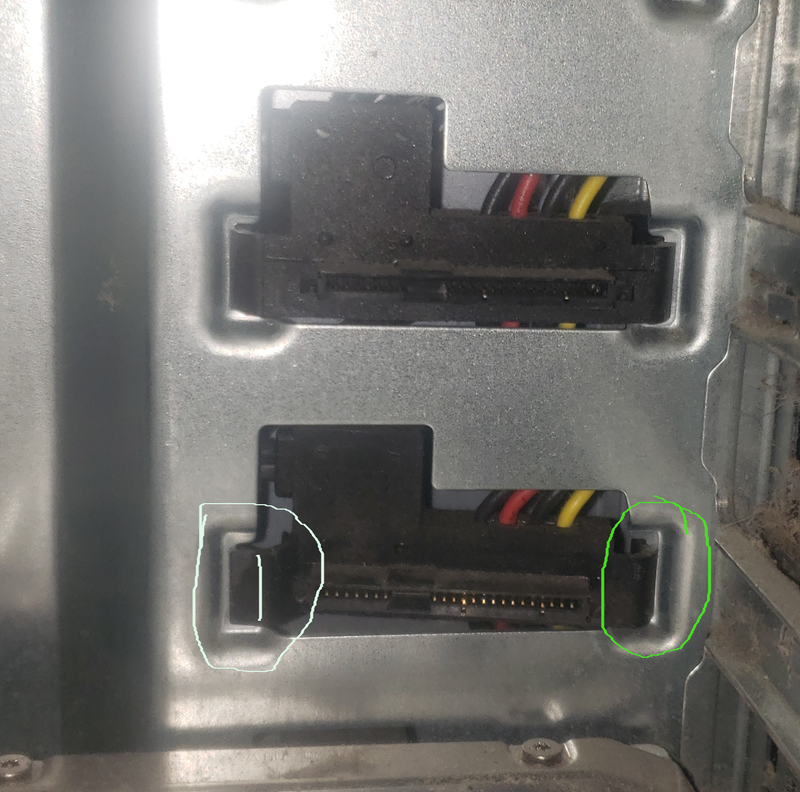

I have attached two images to help anyone visualize the problem. One is far enough back to see the hdd below the bad connector. the other is a cropped and blown up image (with some shaky looking circles drawn in) you can see the slightly twisted socket... doesn't look like much but its enough to keep an hdd from connecting.

The circles are a poor attempt by me to show exactly where the damage is.

Left side is broken along the vertical shaky line shows right where it is cracked. The right side appears to be dislodged from its holder enough to allow the skew. I can't realign

it by hand and I'm afraid if I use pliers I will almost surely break it worse.

it by hand and I'm afraid if I use pliers I will almost surely break it worse.

Solved! Go to Solution.

Accepted Solutions

05-14-2022 03:04 PM - edited 05-15-2022 09:58 PM

This is from a prior document I put together for our IT guys, and the tips also work for the Z800/Z820/Z840 workstations. I tuned it up a bit for you... My recall is that the drive drawers for the ZX00/ZX20/ZX40 are all pretty much interchangable. I can get you the Assembly Part Numbers to search eBay for if you need that.

I hope you know of the very excellent and inexpensive HP metal 3.5 to 2.5" form factor adapters that let you perfectly line up a 2.5" SATA SSD in one of those plastic 3.5" slider drawers. Search eBay for 654540-001. My guess is that someone used an improper adapter that did not shift the SATA data/power connectors properly and shoved that in the drive bay, and ended up dislodging the receiving end in the back of the drive bay as a result. I only use these particular HP adapters now in the ZX00/ZX20/ZX40 slider drawers, and they only cost under 10.00 each USD from eBay. Those adapters were made for HP by Foxconn in China and are engineered to fit perfectly. Plus, there are a bunch of these available, HP/Foxconn quality.

Sticky drive drawer slide channels also appear to be one of your workstation's issues. See the Pledge tip below, which changes everything... that stuff is amazing for this purpose.

HP Z600 Z620 Z640 - Remove and Replace the Right Side Cover

Note: These resources are valuable regardless of what right workstation's side panel is being opened. My tip about the wood/hammer below is valuable, and using a rubber hammer can help… metal can mar the aluminum cover if things slip a bit.

Step 1: With all external cables disconnected from the workstation, start with removing the left access panel... that part is easy. For more information about removing the right side access panel, refer to this HP support document:

Z600: https://support.hp.com/us-en/document/c01733186 The video link there did not work for me but the pics in the document lower down below do help.

Z800: https://youtu.be/BdYTFQGd-rg

Z620: Try https://h30434.www3.hp.com/t5/Desktop-Hardware-and-Upgrade-Questions/HP-z620-right-side-panel/td-p/7... Brian’s link at the bottom there might give you some added perspective.

Step 2: Remove the Torx-15 screws that secure the right side panel to the bottom of the chassis. Note that the number of screws varies from model to model. Once you find and remove those screws you're over half way done.

Step 3: Slide the right side panel back about half an inch (1.3 cm) and then lift and remove the panel. Note that whether you slide back or down depends on the shape of the slits in the internal metal case that the special machined metal attachment slider posts go into. Those are attached to the right side aluminum cover’s inside face. It is either back or down, never a mix of both.

Note for the Z640: The right side panel needs to slide downward (rather than back) about 0.5 inch and then it can be lifted up and out. It can be hard to get this slid down the first time… I use a soft wood block edge against only the top edge of the aluminum panel, working back and forth. This will allow gentle hammering to get it shifted down the first time. It is much easier to get off after Pledge has been applied, described below.

Before putting the right side panel back on I apply a dab of Pledge to the 9 metal slider posts attached to the inside face of that panel, and even a bit to the edges of the slots those posts need to slide against when the panel is slid back up. You should spray from the can into a little dish and use a Q-Tip to swab with. It does not take much and after Pledge is applied future work is much easier. For the Z640 there are two silver metal bottom tabs you need to unscrew first. They are hidden beneath the right side bottom foot assembly (which has only 1 screw to remove). Then that whole foot assembly slides out. Only then can you see the hidden screws beneath.

For your binding drive drawer channels: Apply a very small amount of silicon grease (or Pledge) to the metal channels the drive sleds travel through… the drive drawers slide much better after that.

Hopefully you can reposition your female “Blind-Mate” receptacle at the back of the drawer bay once you have rear access to that right side. You can find whole sets of those on eBay sometimes.

HP black plastic parts, if broken, can literally be “welded” back together using Gorilla brand liquid (or gel, but slower) superglue. The fumes put off by the cure process can frost nearby plastic parts a bit… I keep a fan running across the area to prevent that. Let things sit overnight for best strength.

PDF of this attached below... Good Luck!

05-14-2022 03:04 PM - edited 05-15-2022 09:58 PM

This is from a prior document I put together for our IT guys, and the tips also work for the Z800/Z820/Z840 workstations. I tuned it up a bit for you... My recall is that the drive drawers for the ZX00/ZX20/ZX40 are all pretty much interchangable. I can get you the Assembly Part Numbers to search eBay for if you need that.

I hope you know of the very excellent and inexpensive HP metal 3.5 to 2.5" form factor adapters that let you perfectly line up a 2.5" SATA SSD in one of those plastic 3.5" slider drawers. Search eBay for 654540-001. My guess is that someone used an improper adapter that did not shift the SATA data/power connectors properly and shoved that in the drive bay, and ended up dislodging the receiving end in the back of the drive bay as a result. I only use these particular HP adapters now in the ZX00/ZX20/ZX40 slider drawers, and they only cost under 10.00 each USD from eBay. Those adapters were made for HP by Foxconn in China and are engineered to fit perfectly. Plus, there are a bunch of these available, HP/Foxconn quality.

Sticky drive drawer slide channels also appear to be one of your workstation's issues. See the Pledge tip below, which changes everything... that stuff is amazing for this purpose.

HP Z600 Z620 Z640 - Remove and Replace the Right Side Cover

Note: These resources are valuable regardless of what right workstation's side panel is being opened. My tip about the wood/hammer below is valuable, and using a rubber hammer can help… metal can mar the aluminum cover if things slip a bit.

Step 1: With all external cables disconnected from the workstation, start with removing the left access panel... that part is easy. For more information about removing the right side access panel, refer to this HP support document:

Z600: https://support.hp.com/us-en/document/c01733186 The video link there did not work for me but the pics in the document lower down below do help.

Z800: https://youtu.be/BdYTFQGd-rg

Z620: Try https://h30434.www3.hp.com/t5/Desktop-Hardware-and-Upgrade-Questions/HP-z620-right-side-panel/td-p/7... Brian’s link at the bottom there might give you some added perspective.

Step 2: Remove the Torx-15 screws that secure the right side panel to the bottom of the chassis. Note that the number of screws varies from model to model. Once you find and remove those screws you're over half way done.

Step 3: Slide the right side panel back about half an inch (1.3 cm) and then lift and remove the panel. Note that whether you slide back or down depends on the shape of the slits in the internal metal case that the special machined metal attachment slider posts go into. Those are attached to the right side aluminum cover’s inside face. It is either back or down, never a mix of both.

Note for the Z640: The right side panel needs to slide downward (rather than back) about 0.5 inch and then it can be lifted up and out. It can be hard to get this slid down the first time… I use a soft wood block edge against only the top edge of the aluminum panel, working back and forth. This will allow gentle hammering to get it shifted down the first time. It is much easier to get off after Pledge has been applied, described below.

Before putting the right side panel back on I apply a dab of Pledge to the 9 metal slider posts attached to the inside face of that panel, and even a bit to the edges of the slots those posts need to slide against when the panel is slid back up. You should spray from the can into a little dish and use a Q-Tip to swab with. It does not take much and after Pledge is applied future work is much easier. For the Z640 there are two silver metal bottom tabs you need to unscrew first. They are hidden beneath the right side bottom foot assembly (which has only 1 screw to remove). Then that whole foot assembly slides out. Only then can you see the hidden screws beneath.

For your binding drive drawer channels: Apply a very small amount of silicon grease (or Pledge) to the metal channels the drive sleds travel through… the drive drawers slide much better after that.

Hopefully you can reposition your female “Blind-Mate” receptacle at the back of the drawer bay once you have rear access to that right side. You can find whole sets of those on eBay sometimes.

HP black plastic parts, if broken, can literally be “welded” back together using Gorilla brand liquid (or gel, but slower) superglue. The fumes put off by the cure process can frost nearby plastic parts a bit… I keep a fan running across the area to prevent that. Let things sit overnight for best strength.

PDF of this attached below... Good Luck!

05-14-2022 06:32 PM

the HP z800 service manual covers how to remove the internal hotswap cable

i would simply replace the cable if it's damaged

https://support.hp.com/us-en/product/hp-z800-workstation/3718645/manuals

https://www.manualslib.com/manual/690474/Hp-Z800.html

https://www.ebay.com/itm/132475921140

05-15-2022 04:19 PM

@SDH wrote:[...] snip

I hope you know of the very excellent and inexpensive HP metal 3.5 to 2.5" form factor adapters that let you perfectly line up a 2.5" SSD in one of those plastic 3.5" slider drawers. Search eBay for 654540-001. My guess is that someone used an improper adapter at did not shift the SATA data/power connectors properly shoved that in and ended up dislodging the receiving end in the back of the drive bay as a result. I only use these particular HP adapters now for the slider drawers, under 10.00 USD from eBay

I have what is probably the predecessor to the SSD adapter you speak of. Its and HP adapter for the Z800 drawers to make 2.5 inch discs work in there. I haven't had to take it out or anything since I've had the Z800, probably pushing a yr now. So won't mess with it unless forced; heh heh.

By the way, many thanks for all the good info. I managed to have the right side panel out before I noticed your message. I wish I had seen it first. I did a lot of hemming and hawing before finally seeing how it had to go. At least I didn't damage it too bad.

Sticky drive drawer slide channels appear also to be one of your workstation's issues. See the Pledge tip below, which changes everything... that stuff is amazing for this problem.

About that: The drive you can see in one of the images in OP has the little tripper device that is part of the sled, broken off. [You can't see the outside end of drive in that picture] Consequently that drawer is stuck... fortunately I don't need it out. At least not right now. Looking it over just a bit I don't see how the tripping mechanism works... but it must be possible to trip it manually. Before I put things back together I'm going to have a go at fixing the stuck sled while I'm at it. And hopefully get a replacement sled.

PS: my fix for the 15/22 socket ... now that I can see it and twiggle it around a little is kind of a copout.

I don't really see a nifty fix for it. I think small wooden wedges from the back side would firm it up to where only a real jamming would dislodge it again. But all I did was since I can wiggle it around a bit from the back side (with right panel off) I just held it in place while siding in a new drive in the old sled and I can feel the plug go home when I press on the sled and hold firmly with other hand from back side of socket.. I'm pretty sure that will hold it until I need to take the disk out, but since its such an easy matter to get that panel off, I can pull the panel if I need to replace or for some reason pull that disk. Yeah, I know its a "cowards way out" but I don't think any amount of glue or whatever will really hold any better than the drive itself holds it. Feels down right sturdy with a disk plugged into it. (still haven't actually tested.... the chassis is still apart as I write)

Since I can get to both sides with the right panel off seems like better to leave well enough alone.

Oh, before I forget, you mentioned something called "Pledge" a few times. You don't mean the furniture polish do you? What is the "Pledge" you speak of?

Thanking you again for all the help. Your post will be saved away for future needs.

Just like to mention I'd dearly love to get my hands on a Z840 with 256 ram and 2x Xeon.... if under $2000

05-15-2022 05:06 PM

egad I almost forgot an important part of this project: The interior panel that covers the 5.25 bays seem to not want to open.

I've included a picture so you'll now exactly what I'm talking about. There is some kind of spring loaded contraption at the top of the panel in the image where I'm pointing with a stick back between that opening; I really can't see a way to get a good picture

But the door or cover that needs opening, you can see by green colored handle on the cover. It swings out left to right. There must be some trick way to release it... but I'm not finding it.

Its covering the 5.25 bays.

I want in there because I'm trying to get a HDD cage to put in those 2 5.25 bays that will hold at least 3 drives and maybe there is one that holds 4 in two 5.25 bays

Do you have any experience with those kind of drive cages with backplane like Icy Dock makes (and lots of other companies)? I'd really like to get 4 more drives in that machine.

05-15-2022 06:33 PM

what you are talking about is the 5.25 bay locking mechanism, that side panel is pulled outwards

at the green stripe approx. 1/4 in

this releases small metal needles that are pushed onto the screw holes of a 5.25 device which is inserted in the 5.25 bay

so to recap, pull the green tab towards you, then remove (or insert) the 5.25 device from the front,...... do note that the front plastic panel on the z800must also be removed as some 5.25 devices are very tight to remove if the front panel is left on

again, all of this is covered in the service manual!!!!!!

05-15-2022 08:45 PM

One of the links that came up in this discussion shows some 30 manuals ....I was wondering which was considered the Service Manual.... Now I see ... Thank you sir.

I wonder if there one of those for xw8600 too? That is the companion HP server I have along with the Z800.

05-15-2022 09:33 PM - edited 05-15-2022 09:40 PM

DGroves and I tag-team together on some of these projects. We've done these so often the HP engineering just comes naturally. Consider that 5.25" release mechanism a "flapper" lock... just pulling it out a bit is enough and hold it out, and then push the 5.25" optical drive from behind towards the front... it will slide right out.

The plastic drive drawers you refer to... right in the center top area of the flat face is a pull-down release. Pull down on that and then you'll be able to rotate that down towards the front which releases the two side plastic rotating latches.

There is a "tool-less" HP adapter for those drawers... about 100.00 each. For 10.00 each with the one I mentioned I'll go ahead and learn to use a screwdriver.

A hot hair dryer or a cooler hot air gun can get spring back into the black plastic parts... heat it up and hold it out a ways, and plunge into cold water (or just hold and wait). Done.

https://support.hp.com/us-en/product/hp-xw8600-workstation/3432827/manuals

https://h30434.www3.hp.com/psg/attachments/psg/Audio/292168/3/xw8600%20tech%20manual%20v5.pdf

05-15-2022 09:35 PM

instead of wondering,........................extend fingers, type in search engine "HP xw8600 service manual"

back to reality................ unless you like collecting obsolete hardware trash the 8600

the case may be the only useable item if it's the one that has the std I/O backplate

instead of the later one that has the I/O ports as stamped cutouts