-

×InformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

-

×InformationNeed Windows 11 help?Check documents on compatibility, FAQs, upgrade information and available fixes.

Windows 11 Support Center. -

- HP Community

- Printers

- 3D Scanning

- Heavier duty turntable?

Create an account on the HP Community to personalize your profile and ask a question

10-17-2017 01:57 PM

I have been using manual turntable solutions and now want to upgrade to an automatic turntable but I want one capable of handling 200 - 300 lbs. I have only just begun my search but I have no list of supported turntables nor can I find a technical description of the turntable interface so I can evaluate other offerings.

I do find turntables made for the photographry market. Is there anyone that uses a large turntable successfully? I would like one i could automate but would accept a solid turntable with a mechanical but not automated control. Any solid information on HP's turntable, successful large turntable installs or just leads to investigate will be appreciated.

Solved! Go to Solution.

Accepted Solutions

10-20-2017 07:00 AM

That is the problem, there is no signal or trigger to know when scanning is done. This is not integrated solution, but it is partial solution for your needs. If you want fully automated turntable you could try to make arduino turntable and to use light sensor. Maybe stripe pattern could be used as a trigger or blue color of the texture scan sequence. It will not be integrated solution, but it could work.

Original David Team Member

10-18-2017 01:36 AM

HP turntable and Capture Stage are made for smaller objects, up to 5 kg on 18cm radius. HP 3D Scanning software V5 does not support 3rd party turntables, but the version 4 does (over the com port). Please check this thread in the old forum:

http://forum.david-3d.com/viewtopic.php?f=6&t=4291&hilit=custom+turntable

Another way to use custom turntable is the SDK.

Original David Team Member

10-18-2017 08:46 AM

Thank you for this information but I do not see myself dropping down to David 4 SW to be able to use a better turntable as I've recently upgraded to a dual camera setup. I also don't see myself spending $1000 for a single axis that is rated to just 5kg/11lbs. I would like to make a single purchase that can be used for a wide range of objects.

Given that the HP Scan SW does not employ the com port now, it seems that all previous Discussion Board solutions appear dated. I will look a bit further into the SDK that you mentioned, as I do program, but I really am not looking for another project at this time.

Perhaps a motorized non-integrated solution for now that could be later integrated is out there. It's an upgrade from my plywood on large caster bearings that I turn by hand now. I'll also explore the work that people have done with the Stepper-Bee controller.

Thank you again. Any additional information or suggestions are welcome.

10-19-2017 11:00 AM

Could you give me more details about the SDK that you mentioned? I did not see any HP 3d Scan SDK in the Support Downlad area. It appears that I have found an arduino based turntable supplied with it's own SDK. and I would like to see how/if I can integrate the two.

With the COM Port support removed in version 5 how are various people integrating their third party turntables?

10-20-2017 04:36 AM

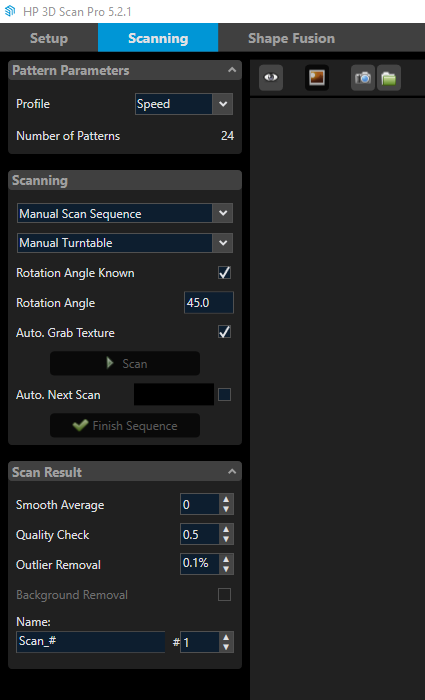

Solution with DAVID 5 and 3rd party turntable, not fully automated but it could work for some users.

In scanning menu choose "Manual Scan Sequence" > "Manual Turntable". If rotation angle is known you can put the check mark and enter a value.

When Scan button is pressed scanning process will start. After each scan scanner is looking for a movement in scene. If there is no movement for 3 seconds scanning will start again. That means that you have 3 seconds to start to rotate the turntable each time when scanning is done. Scanner will wait until there is no movement in scene for 3 seconds, means that turntable finished rotating and scanning will start again. When you made all scans just press "Finish Sequence" button.

What user needs is a turntable with manual control. If you can set rotation angle and rotate turntable with push of a button it would be good.

Original David Team Member

10-20-2017 06:32 AM

Thank you very much for those option settings. I was not aware of those capabilities. I have been feeling that a solution may involve two seperate applications rather than an integrated one. I've recently been wondering what triggers may be exploited. Having an optical one is interesting.

So you say there is a 3 second delay after completion of a scan for the object to begin it's advance. Is there any signal or condition given by the HP 3D SW that could be leveraged by an external application? I'm not too familiar with this HW yet but would there even be a HW signal that I could piggy back on as a trigger for movement?

Bob

10-20-2017 07:00 AM

That is the problem, there is no signal or trigger to know when scanning is done. This is not integrated solution, but it is partial solution for your needs. If you want fully automated turntable you could try to make arduino turntable and to use light sensor. Maybe stripe pattern could be used as a trigger or blue color of the texture scan sequence. It will not be integrated solution, but it could work.

Original David Team Member

10-20-2017 04:35 PM

Awesome! Thanks for that suggested solution. I was wondering the same thing after understanding that the Scan SW has an optical solution that perhaps a similar optical solution can be developed. This is a worthy hack. I'm figuring this to be a good starting point:

https://www.hackster.io/diy-oracle/360-photography-turntable-controlled-via-wifi-4665fe

I'll follow up if I make a solution. If anyone finds a production turntable comporable to this Hackster solution give a should.

Bob