HP Officejet 6500A Plus does not feed paper

Options

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

turn on suggested results

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Guidelines

Ready to level up? Join the Expert Program—

Please log in to submit a nomination.

Thank you

Sorry, there was an error with your nomination, please try again.

Required fields can't be empty, please try again.

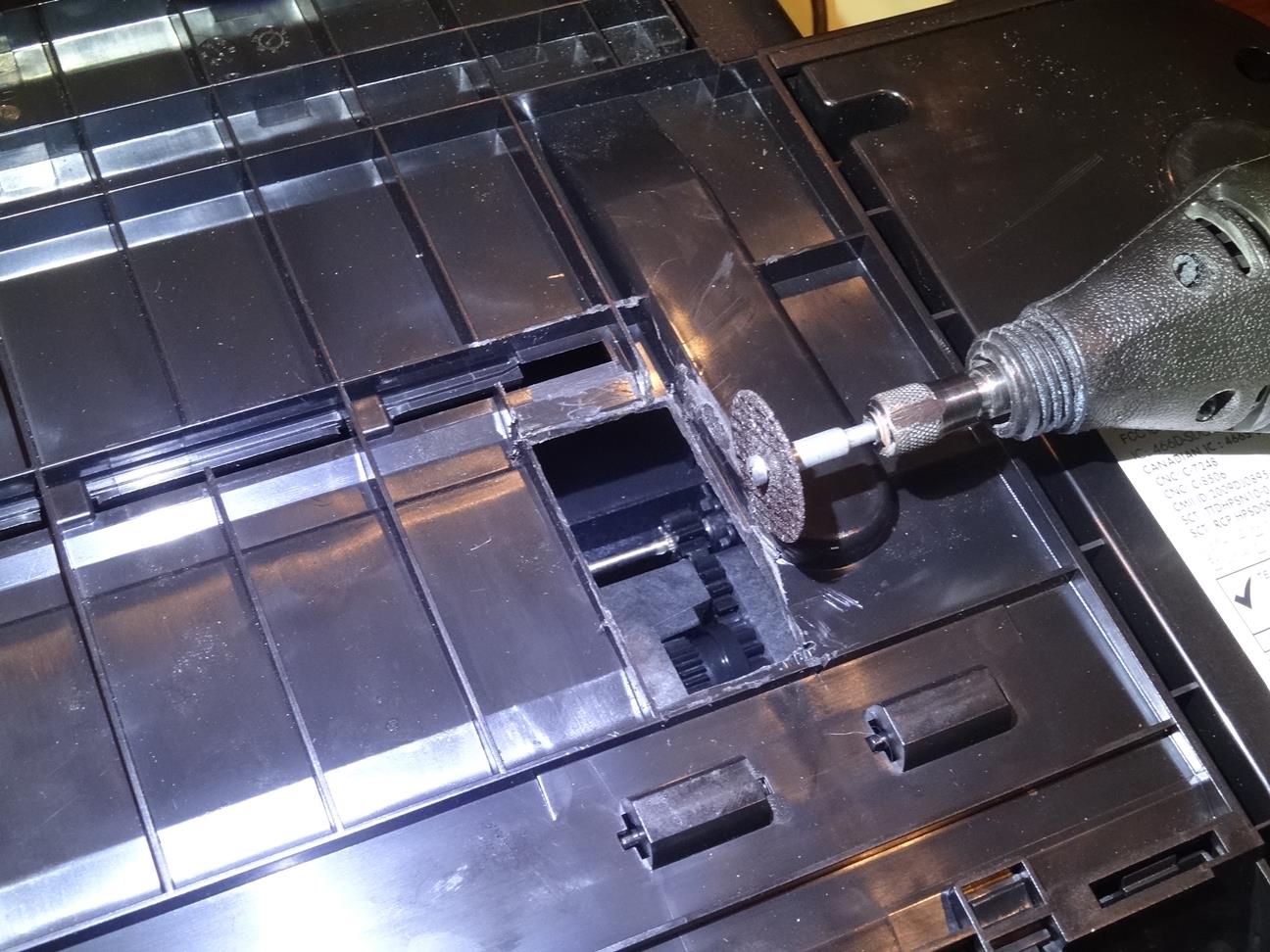

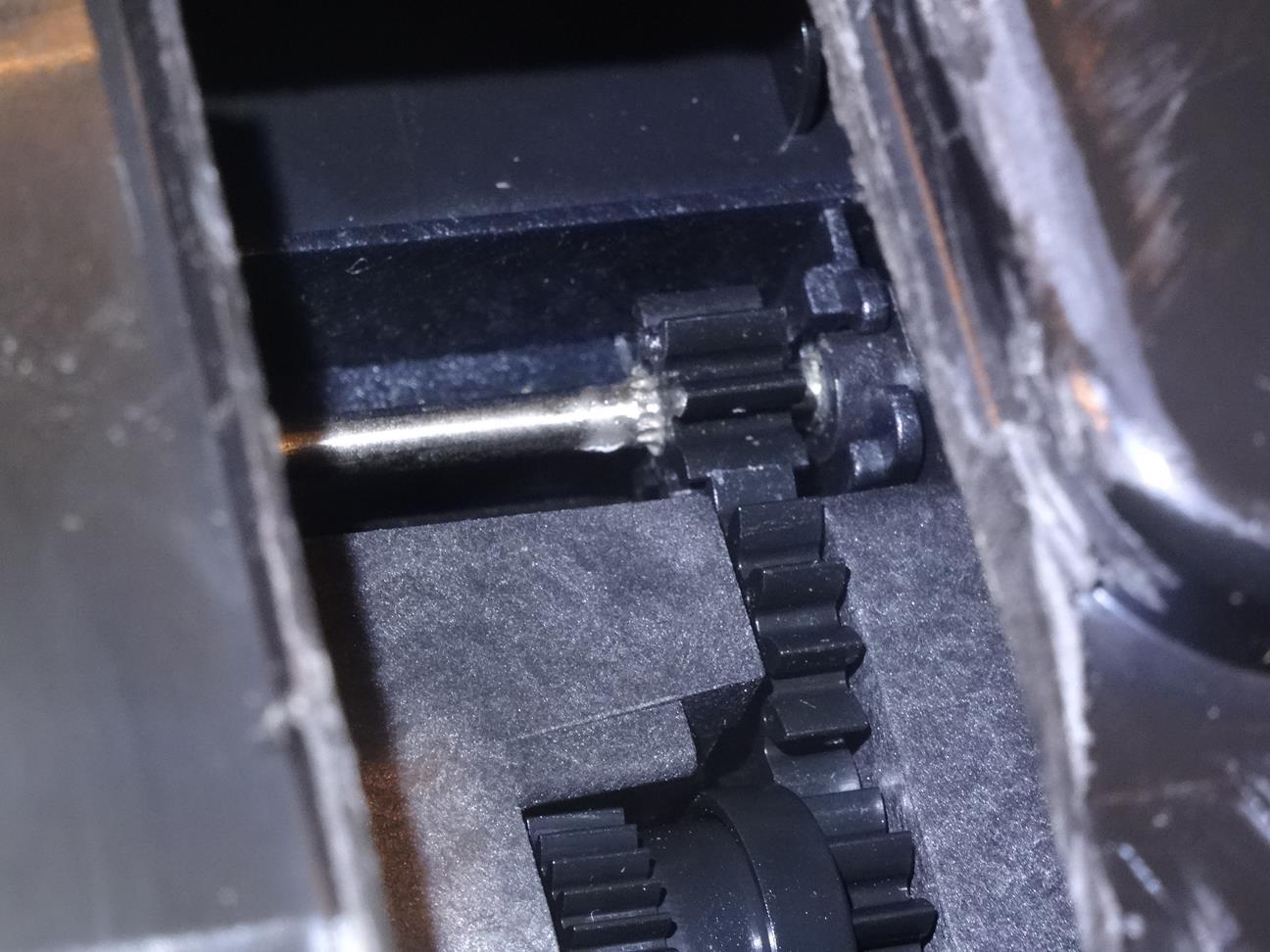

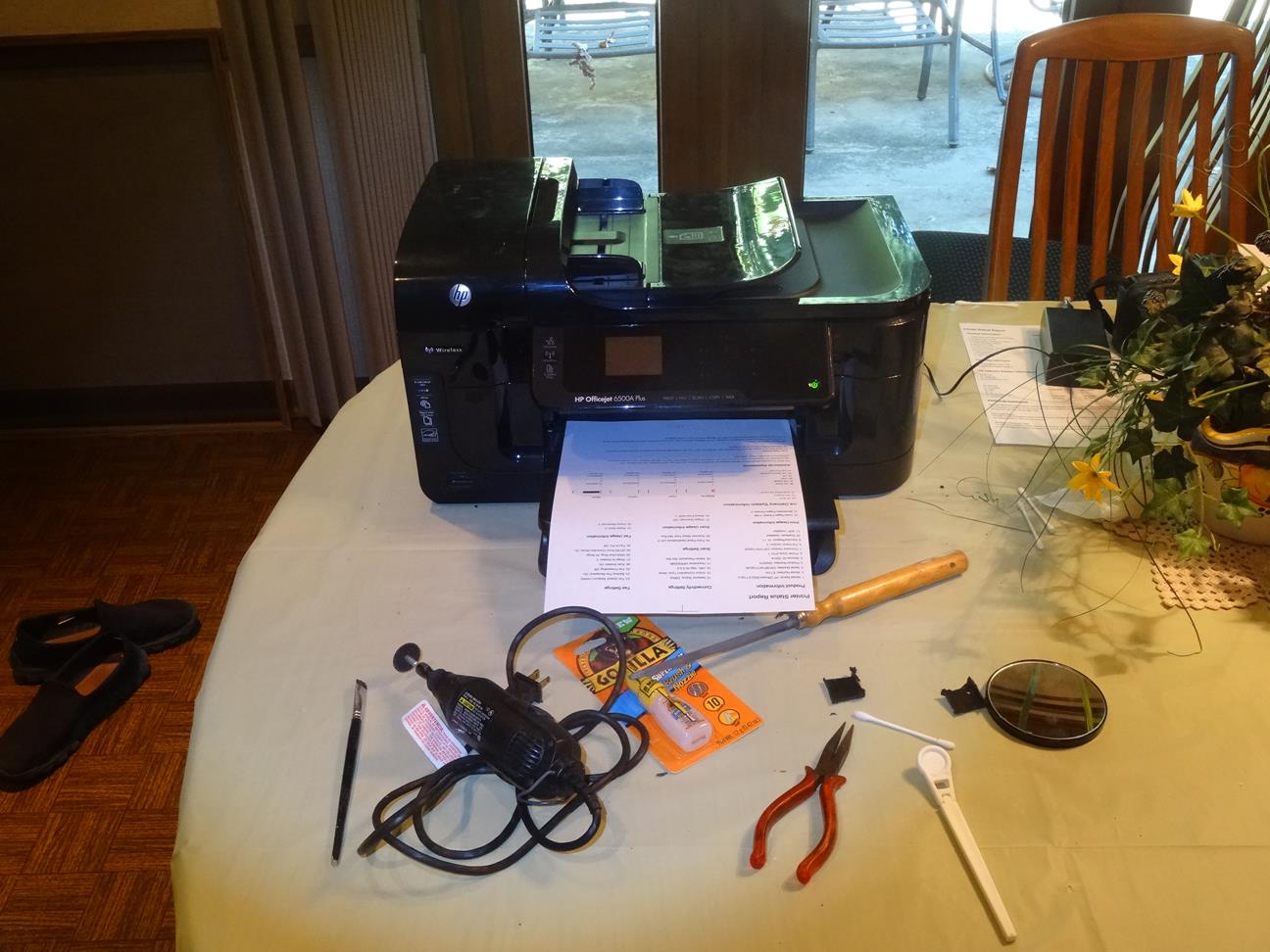

My 6500 OfficeJet did the same thing one day. I had the stripped gear problem (Thanks HP for a plastic gear on a metal shaft) so I followed the same steps. (Thx Moonpatrol). Not wanting to poke glue around the inside of my printer with my phone in there I made the job a bit easier by drilling a 3/4 hole in the bottom tray directly below where the gear is located. I first put some duct tape over where the hole was to be drilled to catch any bits and debris. Once I drilled the hole on slow speed due to plastic, the access was perfect. Flashlight through the hole, glue on toothpick coming in the front onto the metal spline, then slid the gear over it being very careful not to get glue anywhere else. As for the glue I used construction adhesive opting not to use epoxy as it is messing in tight spots like this and felt it was overkill. Hope that helps others. Picture above shows the gear and the glue (white stuff) properly applied. Takes 24 hours but once it dries, it's permanent

My 6500 OfficeJet did the same thing one day. I had the stripped gear problem (Thanks HP for a plastic gear on a metal shaft) so I followed the same steps. (Thx Moonpatrol). Not wanting to poke glue around the inside of my printer with my phone in there I made the job a bit easier by drilling a 3/4 hole in the bottom tray directly below where the gear is located. I first put some duct tape over where the hole was to be drilled to catch any bits and debris. Once I drilled the hole on slow speed due to plastic, the access was perfect. Flashlight through the hole, glue on toothpick coming in the front onto the metal spline, then slid the gear over it being very careful not to get glue anywhere else. As for the glue I used construction adhesive opting not to use epoxy as it is messing in tight spots like this and felt it was overkill. Hope that helps others. Picture above shows the gear and the glue (white stuff) properly applied. Takes 24 hours but once it dries, it's permanent